Instrument cables are used for instrument connection. They are used to connect various instrument equipment, such as temperature sensors, pressure sensors, flow meters, etc., to transmit signals to the control system. Control connection: used to connect various control devices, such as PLC, DCS, etc., to transmit control signals and data signals. Automation system: widely used in automated production lines and industrial control systems, used to transmit various instrument signals and control signals to achieve automated control and monitoring.

Instrument cable is a cable used to connect instruments and control equipment. It has the following advantages, structural features and uses:

MULTIPLE PAIR COPPER, PVC INSULATION, FR-PVC SHEATH INDIVIDUAL SCREEN AND OVERALL SCREEN FR LOW SMOKE HALOGEN SCREEN INSTRUMENT CABLE advantage:

Strong anti-interference ability: Instrument cables usually adopt shielded structures, which can effectively resist external electromagnetic interference and ensure the stability and accuracy of signal transmission.

Good high temperature resistance: Instrument cables are usually made of high temperature resistant materials and can work stably for a long time in high temperature environments.

Good flexibility: Instrument cables usually use small wires with soft outer sheath materials, which are easy to bend and install, and are suitable for complex wiring environments.

Structural features:

Multi-core structure: Instrument cables usually have a multi-core structure, which can transmit multiple signals at the same time to meet the connection needs of a variety of instruments and control equipment.

Shielded structure: Instrument cables usually adopt shielded structures, including aluminum foil shielding and braided shielding, to ensure the stability and reliability of signal transmission.

Corrosion-resistant materials: Instrument cables usually use corrosion-resistant outer sheath materials, which can adapt to harsh usage environments, such as chemical plants, petrochemical industries and other places.

The following MULTIPLE PAIR COPPER, PVC INSULATION, FR-PVC SHEATH INDIVIDUAL SCREEN AND OVERALL SCREEN FR LOW SMOKE HALOGEN SCREEN INSTRUMENT CABLE process selection is for your reference:

REFERENCE: LATEST EDITIONS OF BS EN 50288-7, IEC 60189-1, IEC 60189-2, IEC 60228, IEC 60332-3-24.

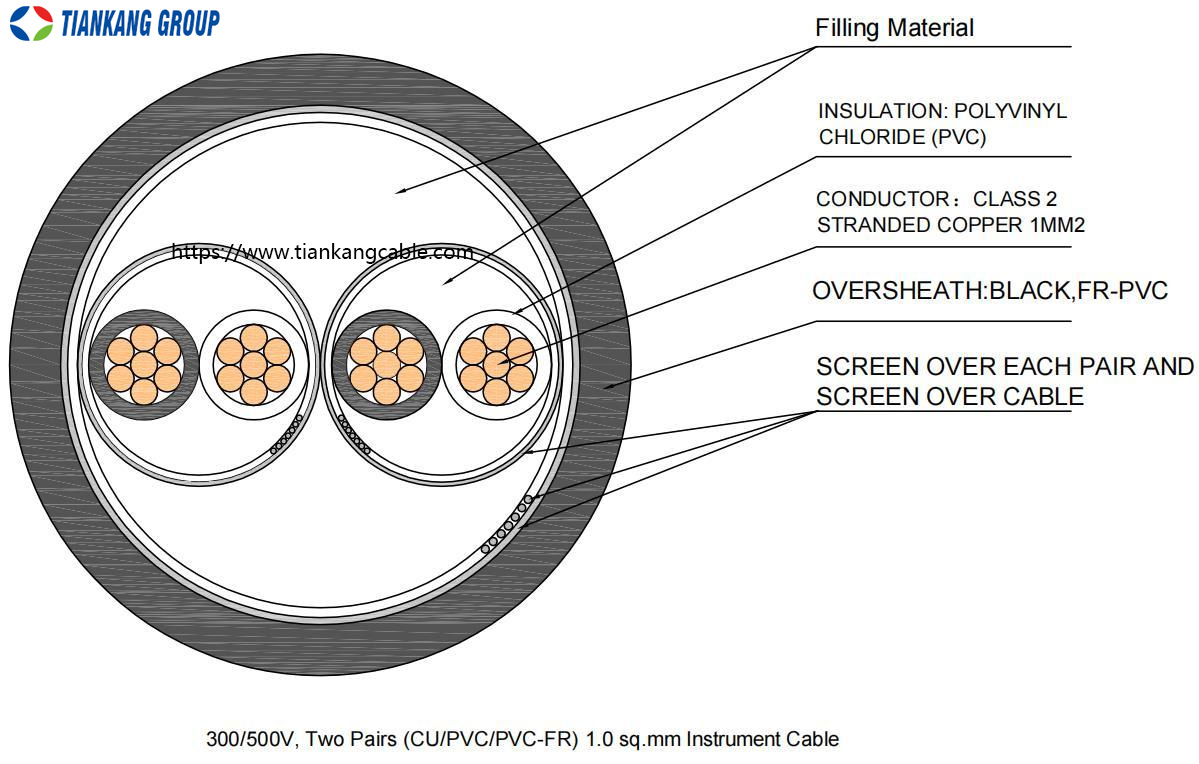

CONDUCTOR:

CLASS 2 STRANDED, COATED OR UNCOATED ANNEALED COPPER, SINGLE PAIR-1.5 mm2

, MULTIPLE PAIR-1.0 mm2

, MAXIMUM DIAMETER, DC RESISTANCE, AND NUMBER OF STRANDS IN ACCORDANCE WITH IEC 60228.

INSULATION:POLYVINYL CHLORIDE (PVC), THICKNESS AND CHARACTERISTICS IN ACCORDANCE WITH BS EN 50288-7.

LAY:INSULATED CONDUCTORS SHALL BE TWISTED TOGETHER TO FORM PAIRS. THE LENGTH OF LAY OF ANY PAIR SHALL NOT EXCEED 50mm.

SCREEN:SINGLE PAIR – SCREEN OVER CABLE ASSEMBLY ONLY; MULTIPLE PAIR – SCREEN OVER EACH PAIR AND SCREEN OVER CABLE

ASSEMBLY: SCREEN(S) SHALL CONSIST OF A COMBINATION OF ALUMINUM-POLYESTER TAPE WITH A MINIMUM OVERLAP OF 20%AND A 0.5 mm2

MINIMUM SIZE TINNED COPPER DRAIN WIRE. SCREEN SHALL BE APPLIED TO ACHIEVE 100 PERCENT COVER OVER

INSULATED CONDUCTORS. SCREEN TAPE SHALL BE APPLIED IN SUCH A WAY AS TO GIVE TOTAL SCREEN ISOLATION FROM OTHERPAIRS.

ASSEMBLY: THE PAIRS SHALL BE CABLED TOGETHER WITH FLAME RETARDANT POLYPROPYLENE FILLERS, AS NECESSARY, AND POLYESTER TAPE OR SPUNBOND TAPE TO MAKE THE FINISHED CABLE ASSEMBLY ROUND.

CORE IDENTIFICATION: THE CORE IDENTIFICATION SHALL BE NUMBERED CORE AS FOLLOWS: NUMBERED CORE: BLACK AND WHITE,CORE COLOUR WITH MARKING NUMBER BEGINNING WITH THE NUMBER “1” PRINTED ON THE CORE EVERY 100mm, ALONG THE LENGTH

OVERSHEATH:

BLACK, SUNLIGHT-RESISTANT, FLAME RETARDANT LIMITED SMOKE POLYVINYL-CHLORIDE (FR-PVC), THICKNESS AND CHARACTERISTICS IN ACCORDANCE WITH BS EN 50288-7.

PRINT LEGEND: A DURABLE MARKING SHALL BE PROVIDED ON THE SURFACE OF THE CABLE AT INTERVALS NOT EXCEEDING ONE METER. MARKING SHALL INCLUDE MANUFACTURER’S NAME, VOLTAGE RATING (V), INSULATING MATERIAL, SHEATH MATERIAL, CONDUCTOR SIZE IN

MM2, NUMBER OF PAIRS, DAY/MONTH/YEAR OF MFG, AND SEQUENTIAL FOOTAGE MARKINGS.

Instrument cable has the advantages of strong anti-interference ability, good high temperature resistance and good flexibility. It adopts multi-core structure and shielded structure and has the ability to connect instrument equipment and control equipment. It is suitable for industrial control systems, automated production lines and other environments. Transmit various instrument signals and control signals to ensure the stability and reliability of signal transmission.