Corrosion resistance: It is suitable for the measurement of some corrosive media and has certain corrosion resistance.

Single Pair-1.5 sq.mm ETFE Thermocouple extension Cable Type K technical requirements:

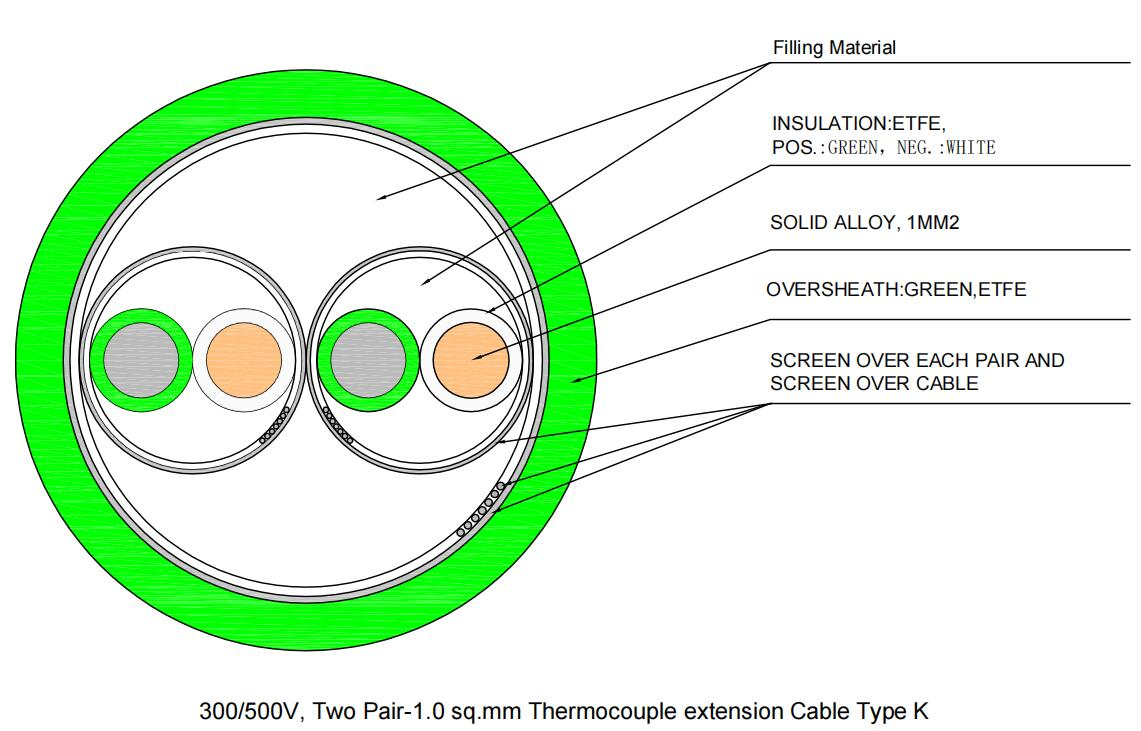

1,Conductor:solid alloy, single pair-1 mm2 , multiple pair-1.0 mm2 , in accordance with iec 60584.positive:nickel- chromium ,negative:nickel.

2,Insulation: ETFE, positive:green ,negative:white,insulated conductors shall be twisted together to form pairs. the length of lay of any pair shall not exceed 50mm.

3,Assembly: the pairs shall be cabled together with flame retardant polypropylene fillers, as necessary, and polyester tape or spunbond tape to make the finished cable assembly round.

4,Screen: single pair – screen over cable assembly only; multiple pair – screen over each pair and screen over cable assembly: screen(s) shall consist of a combination of aluminum-polyester tape with a minimum overlap of 20% and a 0.5 mm2 minimum size tinned copper drain wire. screen shall be applied to achieve 100 percent cover over insulated conductors. screen tape shall be applied in such a way as to give total screen isolation from other pairs.

5,Oversheath:sunlight-resistant, ETFE, operating temperature up to 155 °c, short term up to 180 °c.

6,Print legend: a durable marking shall be provided on the surface of the cable at intervals not exceeding one meter. marking shall include manufacturer’s name, voltage rating (v), insulating material, sheath material, conductor size in mm2, number of pairs, day/month/year of mfg, and sequential footage markings.

7,Factory tests: Single Pair-1.5 sq.mm ETFE Thermocouple extension Cable Type K insulated conductors and assembly jacket shall meet the requirements of bs 7655 and bs en 50363-3. in additiona, cable shall meet the requirements of iec 60584 and completed cable shall be flame retardant to iec 60332-3-24 category c.

Contact: Mr Li

Phone: +86-18226665885

Tel: +86-0550-7788337

Email: sales@tiankangcable.com

Add: No.20# RenHe South Road,TianChang,AnHui Province,China